Manufacturer of tools and technologies for Nondestructive Testing (NDT)

OKOndt GROUP represents a group of companies with more than 30 years of experience in the research, development, and manufacture of NDT products. Our industrial clients around the world are committed to ensure the highest levels of operational safety, quality, and reliability. Unlike other NDT suppliers, OKOndt GROUP provides highly reliable technical solutions at affordable prices, allowing customers to maintain excellent operational stability at a minimum cost.

OKOndt GROUP offers both a standard line of NDT instruments and custom equipment and probes built to individual customer specifications and for special materials. In addition to portable devices, we also build large, integrated inspection systems, covering most NDT technologies. Our significant investment in research and development allows us to provide optimized solutions for all of our NDT customers.

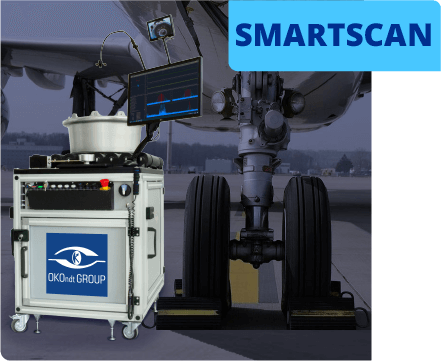

Smartscan FA in India

Commissioning and training on the Aircraft Wheel Inspection System Smartscan FA at an Aircraft Solution Provider in Delhi, India.

ETS2-73 is the mechanized scanning device for the manual testing by eddy-current method for presence of the surface cracks.

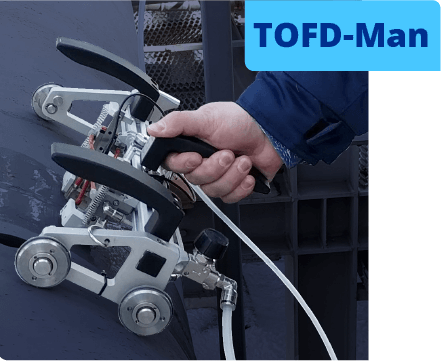

TOFD assures a great accuracy for comfortable measuring the critical size of defects. The accuracy of better than ±1mm can be obtained in a wide range of material thickness.

OKOndt GROUP companies supply NDT equipment to more than 70 countries

We produce various NDT instruments – from handheld flaw detectors to complex automated inspection systems, which are available worldwide through our network of distributors. In addition to sales, we provide post-sale and warranty services for all our products.

Our equipment utilizes a variety of state-of-the-art methods and techniques for nondestructive testing, including ultrasound, phased array, time-of-flight diffraction (ToFD), electromagnetic acoustic (EMA), eddy current, eddy current array, as well as a wide range of other conventional and custom approaches. We specialize in identifying the appropriate technique or combination of techniques to meet your specific needs.

Our flaw detectors are commonly used in the following industrial sectors:

- railroad

- power & aerospace,

- gas and oil & metallurgy,

- machine building & manufacturing.

The equipment produced by OKOndt GROUP improves the quality of our customers’ finished products and enhances the safety of their infrastructure.

Eddy current techniques are applied in nondestructive testing of surface and sub-surface layers (detection of metal discontinuities), structure analysis, estimation of coat thickness, dimensions, chemistry, and heat treatment quality. Eddy current testing is based on the analysis of the interaction between external and eddy current electromagnetic fields that are induced in test objects. Eddy currents are electric current loops which are excited in a conductor while changing the magnetic field that permeates it. The distinctive feature of eddy current inspection is that it can be performed without any contact between a flaw detector and object under test. The interaction is normally achieved at a short distance which is, nevertheless, sufficient for moving the probe relative to the object. This enables the procurement of excellent measurements even when test objects are moving at a high rate of speed.

The electromagnetic acoustic (EMA) technique is a combined method of nondestructive testing based on three effects of the interaction between magnetic fields and the test object: magnetostrictive, magnetic, and electrodynamic effects. The electrodynamic effect is caused by inducing eddy currents in a conductive material that interact with constant magnetic field, which, in its turn, initiates crystal-lattice vibrations (whereas elastic acoustic oscillations occur due to mechanical stresses). EMA transducers are capable of generating horizontally & vertically polarized, longitudinal, shear, Lamb, and Rayleigh waves. Horizontally polarized shear waves have minimum attenuation, diffraction, and metal structure refraction coefficients. The EMA technique allows for noncontact ultrasonic examination of material integrity at high temperatures.

NDT ultrasonic inspection techniques allow the identification of defects located at a considerable depth in various materials, products, and weld joints. Compared to other nondestructive testing methods, ultrasonic flaw detection has significant advantages: a high sensitivity to the most hazardous defects like cracks or incomplete penetration; high capacity; and the ability to supervise the testing directly from an operator’s workplace with no process interruption – all at low operational cost. Ultrasonic examination is applied in a wide range of industries: power, heavy machinery, railroad, ship building, and the chemical sector. Hundreds of thousands of meters of structural welds, tens of thousands of pipe joints, boiler units, rail weld joints, as well as the quality of pressurized tank parts, forgings, tubes, rolled plates and other products are annually inspected by means of ultrasonic NDT techniques.

MEET US AT WORLD FAMOUS ANNUAL CONFERENCES AND EXHIBITIONS

Saudi Rail 2024

Riyadh, Saudi Arabia

Airlines for America (A4A 2024)

Nashville, Tennessee, USA

20th WCNDT (2024)

Incheon, South Korea

UPCOMING EVENTS

Eurasia Rail

June 18-20, 2025

Istanbul, Turkey

Visit the OKOndt Group at Booth No. 2547, Hall 2!

Come and discover our new solutions for ultrasonic and eddy current testing of rails.